New technologies and enhancing customer experience are key drivers for companies investing in digital transformation, but the most important reason for prioritizing this shift is that it will allow them to leverage entirely new opportunities for growth. However, with the speed of digital transformation accelerating at a furious pace, companies need to quickly adapt their working environment to keep up. This graphic from mCloud unearths the origins of the connected worker, and explores the potential applications of connected devices across industries.

The Rise of the Connected Worker

The mass adoption of smart devices has sparked a new wave of remote work. This type of working arrangement is estimated to inject $441 billion into the global economy every year, and save 2.5 million metric tonnes of CO2 by 2029—the equivalent of 1,280 flights between New York and London. However, flexible or remote working looks different depending on the industry. For example, in the context of business services such as engineering or manufacturing, employees who carry out different tasks remotely using digital technologies are known as connected workers. The term is not a one-size-fits-all, as there are many different types of connected workers with different roles, such as operators, field workers, engineers, and even executives. But regardless of an individual’s title, every connected worker plays a crucial role in achieving digital transformation.

Real Time Data, Real Time Benefits

When workers are connected to assets in real time, they can make better, more informed decisions—ultimately becoming a more efficient workforce overall. As a result, industries could unlock a wealth of benefits, such as:

Reducing human error Increasing productivity Reducing dangerous incidents Saving time and money Monitoring assets 24/7

While connected workers can enhance the potential of industries, the tools they use to achieve these benefits are crucial to their success.

Connected Worker Technologies

A connected device has the ability to connect with other devices and systems through the internet. The connected worker device market is set for rapid growth over the next two decades, reaching $4.3 billion by 2039. Industries such as oil and gas, chemical production, and construction lead the way in the adoption of connected worker technologies, which include:

Platforms: Hardware or software that uses artificial intelligence and data to allow engineers to create bespoke applications and control manufacturing processes remotely. Interfaces: Technologies such as 3D digital twins enable peer-to-peer information sharing. They also create an immersive reflection of surroundings that would have otherwise been inaccessible by workers, such as wind turbine blades. Smart sensors and IoT devices: Sensors that monitor assets provide a more holistic overview of industrial processes in real time and prevent dangerous incidents. Cloud and edge computing: Using the cloud allows workers to communicate with each other and manage shared data more efficiently.

Over time, connected devices are getting smarter and expanding their capabilities. Moreover, devices such as wearables are becoming more discreet than ever, and can even be embedded into personal protective equipment to gather data while remaining unobtrusive.

Real World Applications

With seemingly endless potential, these devices have the ability to provide game changing solutions to ongoing challenges across dozens of industries.

Building Maintenance and Management Facility managers can access real time information and connect with maintenance workers on site to resolve issues quickly. Building personnel can also access documentation and remote help through connected technologies. Task Management Operators in industrial settings such as mining can control activities in remote locations. They can also enable field personnel to connect with experts in other locations. Communications Platform Cloud-based communication platforms can provide healthcare practitioners with a tool to connect with the patient, the patient’s family and emergency care personnel.

By harnessing the power of artificial intelligence, the Internet of Things, and analytics, connected workers can continue to revolutionize businesses and industries across the globe.

Towards a More Connected Future

As companies navigate the challenges of COVID-19, implementing connected worker technologies and creating a data-driven work environment may quickly become an increasingly important priority. Not only is digital transformation important for leveraging new growth opportunities to scale, it may be crucial for determining the future of certain businesses and industries. on

#1: High Reliability

Nuclear power plants run 24/7 and are the most reliable source of sustainable energy. Nuclear electricity generation remains steady around the clock throughout the day, week, and year. Meanwhile, daily solar generation peaks in the afternoon when electricity demand is usually lower, and wind generation depends on wind speeds.As the use of variable solar and wind power increases globally, nuclear offers a stable and reliable backbone for a clean electricity grid.

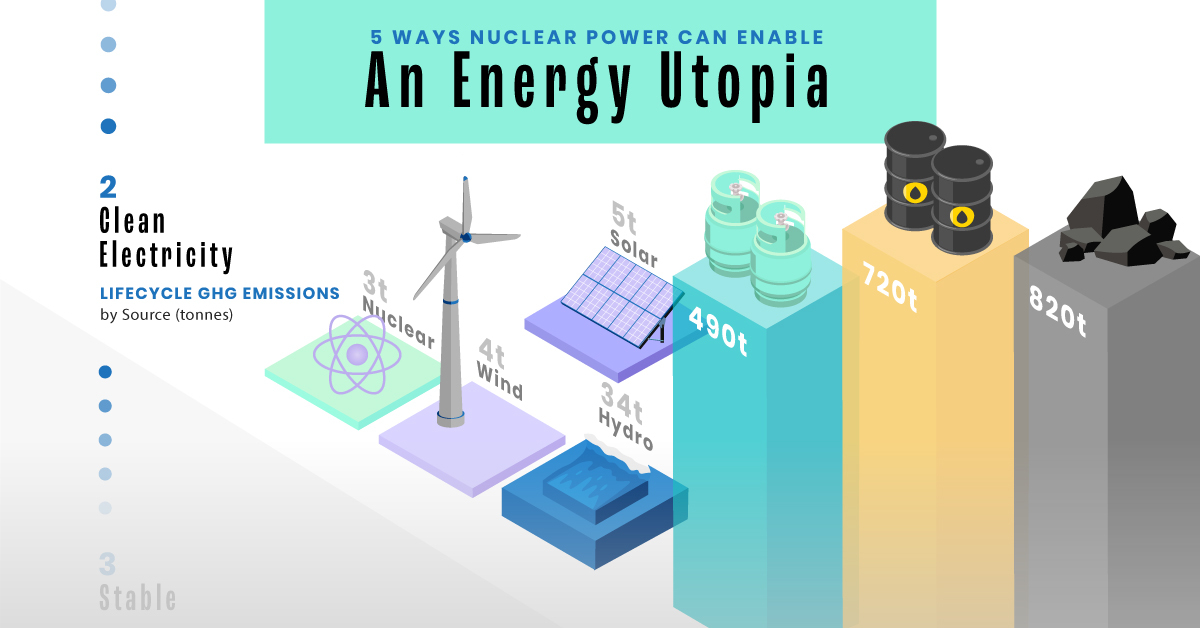

#2: Clean Electricity

Nuclear reactors use fission to generate electricity without any greenhouse gas (GHG) emissions.Consequently, nuclear power is the cleanest energy source on a lifecycle basis, measured in CO2-equivalent emissions per gigawatt-hour (GWh) of electricity produced by a power plant over its lifetime. The lifecycle emissions from a typical nuclear power plant are 273 times lower than coal and 163 times lower than natural gas. Furthermore, nuclear is relatively less resource-intensive, allowing for lower supply chain emissions than wind and solar plants.

#3: Stable Affordability

Although nuclear plants can be expensive to build, they are cost-competitive in the long run. Most nuclear plants have an initial lifetime of around 40 years, after which they can continue operating with approved lifetime extensions. Nuclear plants with lifetime extensions are the cheapest sources of electricity in the United States, and 88 of the country’s 92 reactors have received approvals for 20-year extensions. Additionally, according to the World Nuclear Association, nuclear plants are relatively less susceptible to fuel price volatility than natural gas plants, allowing for stable costs of electricity generation.

#4: Energy Efficiency

Nuclear’s high energy return on investment (EROI) exemplifies its exceptional efficiency. EROI measures how many units of energy are returned for every unit invested in building and running a power plant, over its lifetime. According to a 2018 study by Weissbach et al., nuclear’s EROI is 75 units, making it the most efficient energy source by some distance, with hydropower ranking second at 35 units.

#5: Sustainable Innovation

New, advanced reactor designs are bypassing many of the difficulties faced by traditional nuclear plants, making nuclear power more accessible.

Small Modular Reactors (SMRs) are much smaller than conventional reactors and are modular—meaning that their components can be transported and assembled in different locations. Microreactors are smaller than SMRs and are designed to provide electricity in remote and small market areas. They can also serve as backup power sources during emergencies.

These reactor designs offer several advantages, including lower initial capital costs, portability, and increased scalability.

A Nuclear-Powered Future

Nuclear power is making a remarkable comeback as countries work to achieve climate goals and ultimately, a state of energy utopia. Besides the 423 reactors in operation worldwide, another 56 reactors are under construction, and at least 69 more are planned for construction. Some nations, like Japan, have also reversed their attitudes toward nuclear power, embracing it as a clean and reliable energy source for the future. CanAlaska is a leading exploration company in the Athabasca Basin, the Earth’s richest uranium depository. Click here to learn more now. In part 3 of the Road to Energy Utopia series, we explore the unique properties of uranium, the fuel that powers nuclear reactors.